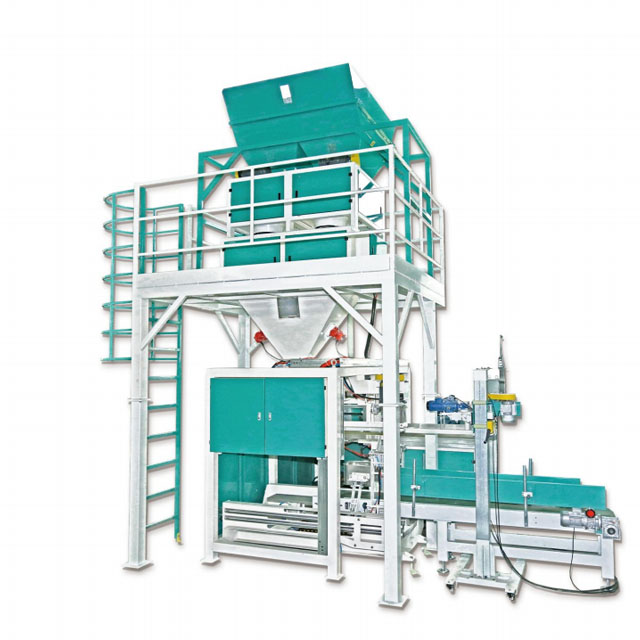

Fully Automatic Packing Machine

| Model |

IKL-PM50 |

| Material |

SUS304 Contact parts |

| Gross Weight |

5T |

| Packing Capacity |

450-600bags/h |

| Weighing Range |

5-50kg or Customized |

| Quantify Precision |

0.2% F/S |

| Power |

10kw |

| Power Supply |

AC 220V/380V 50 HZ 1P/3P Customized |

| Air Source |

0.4~0.6MPa 0.36m3/min |

| Application Materials |

Applicable for packing granular or particle materials such as chemistry, fertilizer, grain, rice, sand, wood pellets, animal feed, urea, phosphate, PP, PE granules, construction materials, etc. |

Advanced Automatic Packaging Line/ Automatic Packing Machine

We provide automatic packing solutions. Our fully automated packaging line eliminates manual intervention, delivering unparalleled efficiency and consistency. By integrating state-of-the-art sensor technology and precision weighing systems, it guarantees exact filling weights every time. Engineered for maximum versatility, the system seamlessly adapts to diverse materials and bag dimensions. Continuous real-time process monitoring and automatic adjustments ensure consistently superior packaging quality, dramatically reducing labor costs and skyrocketing productivity.

Core Advantages

1. High Performance

* Rapid, uniform bag handling, filling, and positioning powered by responsive servo motors.

*Features multi-language HMI and swift, automated bag size changeovers for minimal downtime.

*Quick and easy commissioning for a faster return on investment.

2. Precision Engineered

*Adjustable filling spout to precisely accommodate various bag sizes.

*Integrated bag detection at the spout prevents product spillage while maintaining continuous operation.

*Total bag control throughout the process guarantees perfect seals and optimal finished product presentation.

3. Safety & Ergonomic Design

*High-capacity bag magazine with multiple stacks for extended, unattended operation.

*All product contact surfaces are crafted from hygienic Stainless Steel AISI 304.

*Height-adjustable closing conveyor enhances operator ergonomics and line versatility.

*Generously sized access doors facilitate easy cleaning and routine maintenance.

*Separate, air-conditioned electrical and control cabinets ensure safety, reliability, and component longevity.